Trends for sustainable packaging design

Packaging of today and tomorrow

by Sarah Dorkenwald

Here a coffee-to-go, there a fruit salad or a sandwich on the go, sushi or pizza for dinner — take-away products, delivery food as well as so-called convenience food prepared in a snack-like manner and in ever smaller packaging sizes, mostly packed in plastic, contribute significantly to the increasing packaging waste, in addition to the growing online trade.

The figures from the German NGO Deutsche Umwelthilfe are alarming: 13 billion disposable cups and packaging are consumed in the to-go sector in Germany every year. If you break down the annual consumption of approx. 5.8 billion beverage cups into one day, that’s almost 16 million cups per day. The CO2 emissions for the total amount of disposable waste are 830,000 tons, resulting in 190,000 tons of waste.

And Germany is quite exemplary in this respect. From January 2023, reusable packaging will be compulsory, there is a functioning deposit system and up to 69 percent of household waste will be recycled according to the Federal Environment Agency (as of 2020). In this the recycling rate for plastic packaging, which was previously around 45 percent, is increasing due to the new Packaging Act, which, among other things, stipulates a higher recycling rate for packaging.

What packaging solutions are there that offer convincing answers to developments such as the use of e‑commerce formats, modern lifestyles, but also the increased demand for sustainable packaging designs?

Intelligent reuse systems

he Munich-based company Recup, with its reusable deposit system, is one of the major innovators and pioneers in this field. Throughout Germany, it has successfully introduced a reusable system for coffee cups and, more recently, for lunchboxes. One Recup cup can replace up to 1,000 disposable cups and one Rebowl can replace up to 500 food containers, the startup writes on its website. Especially in hip coffee roasteries and stylish city cafés, the plain mint-colored or mocha-brown cup now seems to be a permanent fixture in the inventory.

The Munich-based start-up hey circle also wants to make a difference and has designed distinctive boxes and bags for online shipping that can circulate up to 50 times before being replaced. Via parcel return, the packaging is returned and can be refilled. The different containers work for all conceivable contents, are easy to clean and fold up small, offer a branding area and anti-theft protection through a seal or lead seal, and thus make a significant contribution to reducing packaging waste in online retail.

Design as an innovator for new materials and packaging concepts

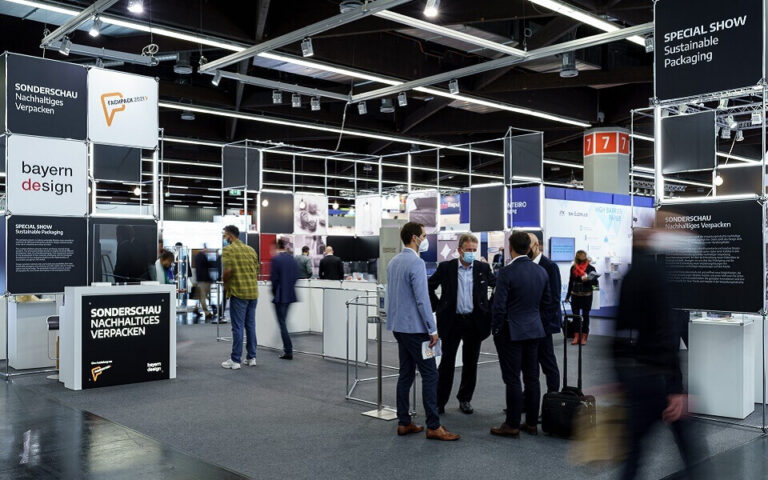

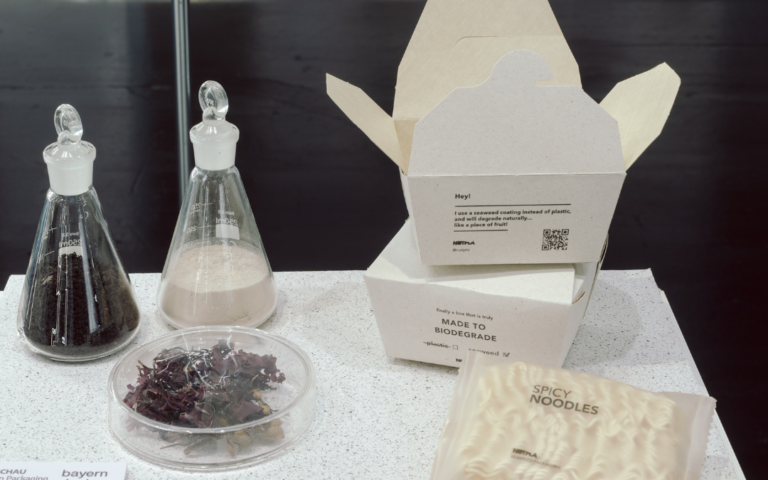

This innovative e‑commerce solution from bayern design was exhibited at FACHPACK 2021. bayern design has been involved in future-oriented, creative and sustainable packaging design solutions for ten years and has so far presented carefully curated special exhibitions together with NürnbergMesse at FACHPACK, the international packaging trade fair for topics relating to packaging, processes and technology.

With a holistic view, current developments in branding, material and added value but also digitalization, smart technologies, finishing, transport and logistics were selected and presented. It became apparent that original and eye-catching design concepts as well as unique packaging interactions are a central component for successful branding in an increasingly visual environment.

But that alone is not enough. Consumers demand intelligent packaging solutions that also take into account sustainable product life cycles, resource conservation and waste production. Circular production concepts and research into alternative materials instead of plastics, cardboard boxes or aluminum packaging are becoming increasingly important for companies.

At FACHPACK 2021 and 2022, bayern design focused on pioneering impulses from materials research as well as implementation and prototyping in order to draw attention to the various development steps up to market maturity of sustainable packaging and to provide important impulses from design for the packaging industry. Design opens up new possibilities that make sustainable packaging attractive and offer added value for corporate culture and brand image.

Zero-waste packaging

Zero-waste packaging made from algae, fungal mycelia or plant fibers, which can be recycled into natural cycles or dissolve completely during use, is a continuing trend. Among others, the packaging concept ‘Meal Bag’ by designer Amelie Graf received special attention. The edible food packaging she developed for portion-packed muesli or pasta is airtight and moisture-resistant to a certain extent. In hot water, the wrapper, whose main ingredient is corn starch, dissolves and can be added to various meals, for example as a sauce binder. As a source of fiber and energy, the wrapper becomes part of the food chain instead of troublesome waste. But even if you don’t use it as food, it is compostable and weathers within a short time or can be renewed and recycled . A beautiful example of a closed material cycle.

While Meal Bag is still a concept — with many awards to its name — London-based startup Notpla has made it to market with its alternative to single-use plastic for food and beverage packaging. Based on seaweed, Notpla has developed an entire system of packaging materials and containers. For example, there is Notpla Film developed to replace conventional flexible packaging made from fossil fuels and based on bioplastics. Unlike these, Notpla Film degrades naturally without releasing microplastics.

Notpla Ooho on the other hand is an unusual packaging solution for on-the-go hydration that replaces the need for plastic cups and bottles. The transparent film in pouch form, which can be filled with liquids, is also created from algae and dissolves 100%. Those who wish can swallow the packaging at the same time. Notpla Pipette enables controlled pouring of single-dose liquids (e.g. cooking oils) and Notpla Pearls is a single-dose sphere made from seaweed for toothpaste, for example.

The Soapbottle by Berlin designer Jonna Breitenhuber is similarly progressive and, above all, aesthetically distinctive. The beautifully shaped container made of soap for shower lotion and shampoo either dissolves gradually during use or, once the bottle is empty, can be rasped and mixed with baking soda for further use as washing powder.

Design for the planet

The alternative Styrofoam packaging from the American company Ecovative was already exhibited at FACHPACK in 2013. Since 2007, Ecovative has been working with mycelia, the thread-like mesh of the fungus, to develop biodegradable composite materials. Their patented Mushroom® Packaging consists of naturally interwoven hemp fibers and mycelial braids, which makes the packaging both malleable and stable, and can be composted after use.

The trend-setting idea here is to operate in coexistence with a healthy planet. The natural, indestructible wealth of ancient living knowledge, what the startup calls “The Forager’s Secret,” inspired Ecovative (even before it became a trend) to look into mycelium materials and biofabrication. Since the material has similar properties to Styrofoam, it is a serious substitute.

A more sustainable packaging culture is possible

bayern design has been demonstrating for ten years with its special exhibitions that there are innovative and sustainable alternatives to conventional packaging. It would be desirable if these forward-looking packaging innovations and design impulses were implemented in existing systems and processes more quickly than has been the case to date, in order not only to serve niches, but to establish the greatest possible impact towards a more sustainable packaging culture.