FachPack 2019:

Premium Environmentally Friendly Packaging

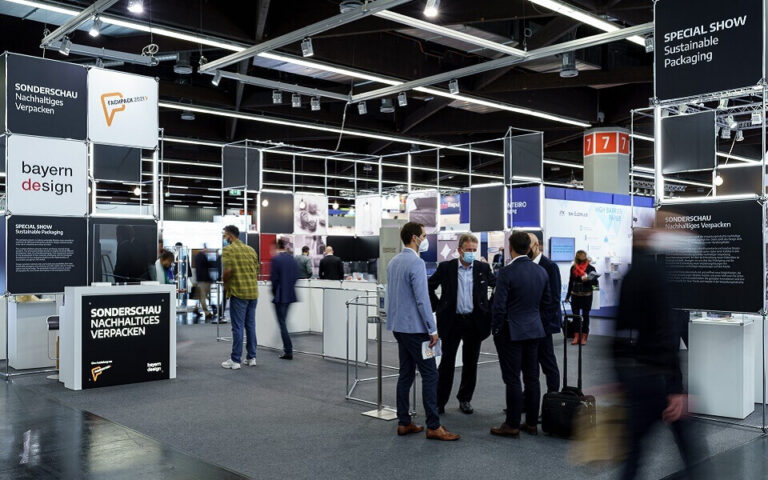

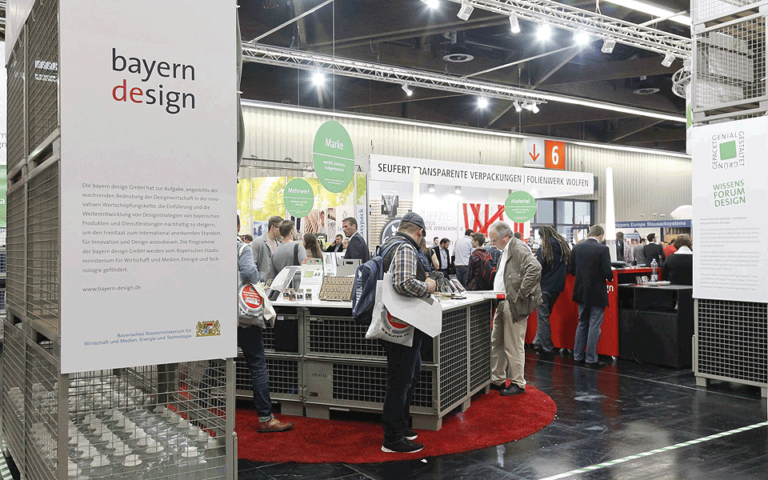

Sustainability and environmental protection are topical themes that also play an increasingly important role in the packaging industry. During FachPack 2019, the leading European trade fair for packaging, technology and processing, bayern design addressed the topic in an exhibition hosted jointly with NürnbergMesse. The close to 40 innovative exhibits from around the world emphasized the process of sustainable packaging design which requires a variety of approaches. The innovative packaging ideas and concepts were originated by designers from Australia, the United Arab Emirates, Germany, Chile, and the United States. They drew upon contemporary trends and materials to present future-oriented and creative designs related to the five themed areas: recycled packaging, resource-preserving materials, reusable packaging and systems, environmentally sound processes, and design as added value. At the concurrent Forum PackBox, industry experts gave brief presentations on premium environmentally friendly packaging.

Recycled Packaging

The goals set by the EU for the recycling of packaging call for new approaches from manufacturers and the recycling industry. By 2025, 55% of all municipal waste will have to be recycled. Thus, numerous current research projects focus predominantly on upcycling plastic waste or reusing it for packaging. What applications can use recyclates and what solutions have companies developed to improve the recycling of packaging?

ARUP

Design agency Arup and social enterprise Goldfinger Factory joined forces to develop a series of charming organic containers for storing foodstuffs including condiments, nuts, cereals and other dry goods, or desk supplies such as paper clips, pens, drawing and painting utensils, and even toys. The lids on the repurposed milk containers are made of recycled wood.

Founded in 2013, Goldfinger Factory is an award-winning social enterprise for sustainable design that offers bespoke concepts for furniture and operates a furniture store. Goldfinger Factory cooperates with an academy where disadvantaged youth can learn to hone their artisanal and artistic skills and learn ways to process recycled materials. All of Goldfinger Factory’s work is guided by the firm’s passion for the circular economy and ensuring an inclusive community. Arup is an independent firm of designers, planners, engineers, consultants, and technical specialists active in all areas of modern economy and society.

PicoFinish/WiHa

he packaging of the PicoFinish® Set stands out because of its unique combination of materials. In addition to an inlay made of environmentally friendly cardboard, Wiha also considered the aspect of sustainability for the transparent slipcase made of organically based PET, 30% of which is produced from renewable raw materials including sugarcane, and 70% of which is made from recycled PET. This means significantly fewer CO2 emissions are generated during production.

Wiha is one of the world’s leading manufacturers of hand tools for professional use in industrial and artisanal applications. Founded 80 years ago as a small family-run operation, the company has evolved into a global player, still owned and run by the Hahn family. Wiha’s mission is to simplify everyday tasks for users through its portfolio of innovative hand tools. The tools are tailored to users’ requirements to increase efficiency, reduce costs, and preserve health.

Descriptions of additional exhibits can be found in our brochure on the Premium Environmentally Friendly Packaging special exhibition at FachPack 2019.

Resource-preserving Materials

What is the optimal way to connect sustainability and packaging? For companies, the answer to this question depends on their industry: Paper manufacturers see the solution in paper-based packaging and producers of plastics and suppliers of aluminum packaging refer to the massive materials savings (which equals using fewer materials while enhancing the functions) and the increasing recyclability of their materials. What does the market have to offer?

TBWA/RAAD

A new twist to handing out samples and a new medium: The OMO Tag resembles any other tag on a piece of clothing but this tag is made of OMO detergent and thus is 100% water-soluble. To promote awareness of an active lifestyle, TBWA\RAAD joined forces with the largest sporting goods retailer in Lebanon and placed the tags on garments which typically become very soiled. The user simply removes the tag and adds it to the load in the washing machine.

TBWA\RAAD was founded in the United Arab Emirates in 2000 with the goal of extending the presence of TBWA Worldwide in the Middle East and in Africa. The network has more than 1,000 members responsible for four main divisions: advertising, digital, shopper marketing, and public relations. The team, known as The Disruption® Company, is the cultural driver for the 21st century business of developing trailblazing ideas for integrating brands into the area’s culture and extending brands’ shares in the future.

Descriptions of additional exhibits can be found in our brochure on the Premium Environmentally Friendly Packaging special exhibition at FachPack 2019.

Reuse Systems

In Germany, reusable packaging is most commonly seen in the beverage aisles of stores – the reuse of glass and PET bottles helps preserve resources. However, the advantages of reusable packaging also can be harnessed in the (commercial) logistics sector where it can be integrated optimally into a circular system concept and its quality tends to prevail over that of disposable packaging. In turn, this offers enhanced protection for the respective products. Also, reusable packaging ensures that less packaging waste is generated during the lifecycle of individual products. Reusable packaging can be made from a variety of materials.

kompackt61

kompackt61 of Nuremberg developed sustainable insulated packaging made from jute for mail-order businesses to use as an ecologically responsible alternative to Styrofoam. Jute has excellent shock-absorbing and insulating properties, ensuring the safe transportation of sensitive foodstuffs and other goods. Also, jute is a natural fiber which makes the entire product, including the wrapping, 100% compostable. Consumers can dispose of it in their organic-waste bins or otherwise compost the material. kompackt61 was elected the winner of the Business Plan Wettbewerb Nordbayern by BayStartUP.

LastSwab

The LastSwab team – Kåre Frandsen, Isabel Aagaard, and Nicolas Aagaard – is committed to creating sustainable alternatives for items used daily. Approximately 18 months ago, the team decided to tackle the problem of 550 billion cotton swabs being produced every year, a large percentage of which pollute oceans and beaches. The solution is LastSwab: The case is made of bio-degradable plastic, the rod is made of nylon, and the tip is made of silicone. Because LastSwab can be cleaned easily and thoroughly, it can be used over and over again, thus saving resources and protecting the environment.

Descriptions of additional exhibits can be found in our brochure on the Premium Environmentally Friendly Packaging special exhibition at FachPack 2019.

Evironmentally friendly Processes

Environmentally sound processes are part of all the sustainable corporate strategies that have become deeply rooted in many companies. Measures include improving the energy efficiency of equipment and reducing waste and materials (e.g., by developing thinner films). In addition, companies are choosing to use materials that do not leave a large ecological footprint.

Arekapak

Arekapak packaging is genuine, ecological, and stands out due to its distinctive aesthetics. The versatile packaging is robust, heat- and cold-resistant, and has an organic water-repellent surface.

Arekapak designs sustainable product packaging made from Areca palm leaves which are agricultural byproducts accrued in large volumes in India. The leaves can be pressed into shape using only heat and pressure, no chemicals. This is why the packaging is 100% natural and can be reinserted into the natural cycle completely at the end of its lifespan.

Descriptions of additional exhibits can be found in our brochure on the Premium Environmentally Friendly Packaging special exhibition at FachPack 2019.

Design as added Value

Design increasingly is deemed to be the key to sustainable economic success and acts as a storefront drawing attention to companies. Good products benefit from well-thought-out and well-structured packaging design.

SOAPBOTTLE is packaging made of soap. As the liquid content of the container is being used, the soap exterior slowly dissolves. Empty containers can be used as hand soap or processed into detergent. Because it is made of natural ingredients, soap is bio-degradable and does not add to landfills. The concept plays with the process of dissolving, the transformation of objects, and the individuality resulting from these elements.

Jonna Breitenhuber completed a one-year preliminary study program in design at Werkbund Werkstatt in Nuremberg and then studied industrial design at Ostbayerische Technische Hochschule in Regensburg. She attained a master’s degree in product design in 2019 from Universität der Künste in Berlin. SOAPBOTTLE was a component of Breitenhuber’s final project.

Descriptions of additional exhibits can be found in our brochure on the Premium Environmentally Friendly Packaging special exhibition at FachPack 2019.